- The first manufacturer to earn DNV’s AM manufacturer certification for binder jetting technology, Aidro was awarded the qualification using the Desktop Metal Shop System™

- Aidro also achieved the highest level of DNV’s AM manufacturer certification for laser powder bed fusion, which included “part qualification for critical level AMC 3” of a 316L valve body

- Based in Northern Italy, Aidro has more than 40 years of experience in the design and production of valves and manifolds, as well as hydraulic and fluid power systems using both traditional and additive manufacturing (AM) methods

- Aidro’s new DNV certifications demonstrate the company’s leadership helping energy, oil & gas, maritime, and other industries transition to Additive Manufacturing 2.0 with confidence

Desktop Metal, Inc. (NYSE: DM) today announced that its Aidro subsidiary, a pioneer in the volume production of next-generation hydraulic and fluid power systems through metal additive manufacturing (AM), has achieved the first-ever global AM Manufacturer certification from DNV, the world’s leading risk management and quality assurance society for the oil & gas and maritime industries, for two metal printing technologies.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20230413005163/en/

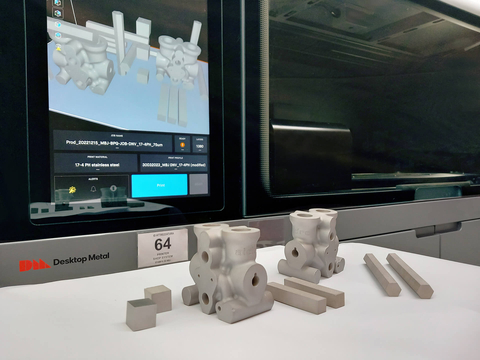

Aidro received the industry’s first certification of qualification from DNV for binder jetting using the Desktop Metal Shop System™ for 3D printing 17-4PH stainless steel parts. The printer is shown here with two valves and coupons printed in 17-4PH. (Photo: Business Wire)

DNV has awarded two certifications, DNV-SE-0568 and DNV-ST-B203, to Aidro’s facility in Taino, Italy. These certifications are recognized globally and were designed in specific support of the mission-critical energy value chain, which includes the maritime and oil & gas industry.

The certifications follow a rigorous review process by DNV, including an audit of Aidro’s facility, metal AM processes qualification, as well as qualification of parts produced by Aidro through AM methods, including mechanical, microstructural, and macrostructural tests. To achieve AMC 3 level certification for laser powder-bed fusion, DNV qualified a specific 316L part produced by Aidro for a customer, as well as a 17-4PH part for binder jetting AMC 1 level certification.

“Our team is incredibly proud to receive this global certification for binder jetting and laser powder bed fusion,” said Valeria Tirelli, President and CEO of Aidro, based in Taino, Italy. “The rigorous process used by DNV will enhance industry confidence in these additive manufacturing methods and continue to support the transition of the demanding energy, oil & gas, and maritime industries toward Additive Manufacturing 2.0. Customers taking the leap into the AM 2.0 future are already realizing incredible benefits, including performance enhancements, lighter weight parts, distributed on-demand manufacturing and digital inventory that reduces the need for physical stock.”

Desktop Metal Founder and CEO Ric Fulop noted that Aidro’s binder jetting certification was enabled by the Desktop Metal Shop System™ printing 17-4PH stainless steel. “Aidro’s binder jetting certification showcases the great performance and reliability of the Shop System, and its ability to serve the most demanding industries such as the oil & gas industry,” Fulop said. “We congratulate all of our Team DM employees at both Aidro and Desktop Metal who contributed to this achievement.”

DNV said Aidro’s qualification is an important step for the mission-critical industries to move into a new era of digital manufacturing.

"We congratulate Aidro for being the world's first in the industry to receive DNV's qualification for Binder Jetting Technology (BJT) at AMC 1 level and AMC 3 level for Laser Beam Powder Bed Fusion technology (PBF-LB). We look forward to continuing close cooperation with Aidro to drive the digitalization shift in manufacturing and providing them and their customers with assurance and confidence in AM products as their use grows across the energy spectrum," said Dr. Sastry Kandukuri, Global Practice Lead on Additive Manufacturing at DNV's Technology Centre in Oslo, Norway.

"Due to the significant impact additive manufacturing will have on the future energy value chain, we emphasize the importance of producing components that meet industry standards. The DNV facility qualification certificate serves as a crucial quality indicator, confirming that a manufacturer and their facility have met the necessary standards for producing critical components for energy applications. The highly productive collaboration between DNV and Aidro has played a significant role in Aidro's commitment to excellence in this field, and DNV is proud to have been a part of it," added Kandukuri.

Aidro has been a leader in driving AM adoption in the energy sector. Aidro’s work with DNV began in 2018, when Aidro contributed to the drafting of the guidelines that became the basis of the DNV-ST-B203 standard. Furthermore, Aidro also has collaborated with the American Petroleum Institute and AM Energy to develop standards and promote the use of AM in the energy industry.

“As the Chairman of the AM Energy network and as the AM Lead in Equinor, an international energy company and one of the end users in the AM ecosystem, I congratulate Aidro for their great achievement of becoming one of the first suppliers certified as an AM factory in the Energy Industry,” said Brede Laerum. “Digital inventories together with on-demand manufacturing of spare parts will transform the supply chain and ensure that we can home source production of parts so we can become more cost efficient, sustainable, improve supply resilience and promote local value creation.”

About Desktop Metal

Desktop Metal (NYSE: DM) is driving Additive Manufacturing 2.0, a new era of on-demand, digital mass production of industrial, medical, and consumer products. Our innovative 3D printers, materials, and software deliver the speed, cost, and part quality required for this transformation. We’re the original inventors and world leaders of the 3D printing methods we believe will empower this shift, binder jetting and digital light processing. Today, our systems print metal, polymer, sand, and other ceramics, as well as foam and recycled wood. Manufacturers use our technology worldwide to save time and money, reduce waste, increase flexibility, and produce designs that solve the world’s toughest problems and enable once-impossible innovations. Learn more about Desktop Metal and our #TeamDM brands at www.desktopmetal.com.

Forward-Looking Statements

This press release contains certain forward-looking statements within the meaning of the federal securities laws. Forward-looking statements generally are identified by the words “believe,” “project,” “expect,” “anticipate,” “estimate,” “intend,” “strategy,” “future,” “opportunity,” “plan,” “may,” “should,” “will,” “would,” “will be,” “will continue,” “will likely result,” and similar expressions. Forward-looking statements are predictions, projections and other statements about future events that are based on current expectations and assumptions and, as a result, are subject to risks and uncertainties. Many factors could cause actual future events to differ materially from the forward-looking statements in this document, including but not limited to the risks and uncertainties set forth in Desktop Metal, Inc.'s filings with the U.S. Securities and Exchange Commission. Forward-looking statements speak only as of the date they are made. Readers are cautioned not to put undue reliance on forward-looking statements, and Desktop Metal, Inc. assumes no obligation and does not intend to update or revise these forward-looking statements, whether as a result of new information, future events, or otherwise.

View source version on businesswire.com: https://www.businesswire.com/news/home/20230413005163/en/

Contacts

Media Relations:

Sarah Webster

sarahwebster@desktopmetal.com

(313) 715-6988

Investor Relations:

Jay Gentzkow

jaygentzkow@desktopmetal.com

(781) 730-2110