Case introduction

The client we visited this time is a certain chemical and biological engineering Co., Ltd. Their main business is engaged in the research and development, design, and manufacturing of chemical engineering, biological engineering, H-protection engineering, pressure vessel contracting, and engineering equipment. It is a company with comprehensive capabilities in research and development, design, manufacturing, engineering, and services.

Customer process requirements: The material of the processed workpiece is S30408, with dimensions (20.6 * 2968 * 1200mm). The processing requirements are a Y-shaped groove, a V-angle of 45 degrees, a V-depth of 19mm, and a blunt edge of 1.6mm.

Based on the customer's process requirements, we recommend the GMMA-80A steel plate beveling machine:

Product Characteristic:

• Dual speed plate edge milling machine

• Reduce usage costs and alleviate labor intensity

• Cold cutting operation, no oxidation on the groove surface

• The slope surface smoothness reaches Ra3.2-6.3

• This product has high efficiency and simple operation

Product parameters

| Product Model | GMMA-80A | Processing board length | >300mm |

| Power Supply | AC 380V 50HZ | Bevel angle | 0°~60°Adjustable |

| Total power | 4800w | Single bevel width | 15~20mm |

| Spindle speed | 750~1050r/min | Bevel width | 0~70mm |

| Feed Speed | 0~1500mm/min | Blade diameter | φ80mm |

| Thickness of clamping plate | 6~80mm | Number of blades | 6pcs |

| Clamping plate width | >80mm | Workbench height | 700*760mm |

| Gross weight | 280kg | Package size | 800*690*1140mm |

The model used is GMMA-80A (automatic walking beveling machine), with dual electromechanical high power and adjustable spindle and walking speed through dual frequency conversion. It can be used for processing steel, chromium iron, fine grain steel, aluminum products, copper and various alloys. Mainly used for groove processing operations in industries such as construction machinery, steel structures, pressure vessels, ships, aerospace, etc.

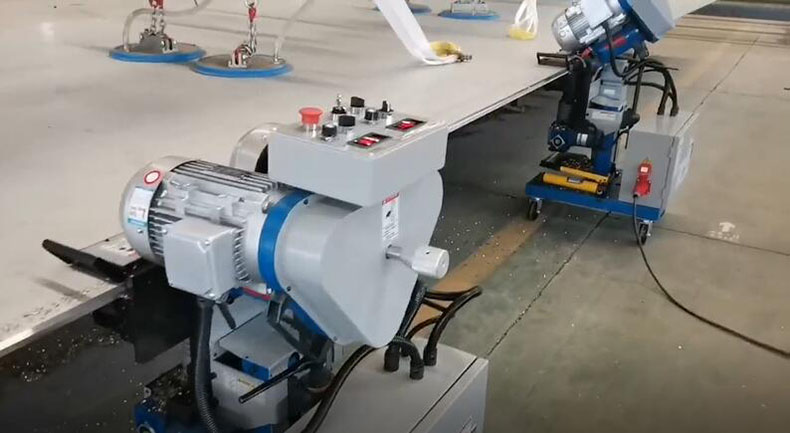

On site delivery effect display:

The effect of using a 20.6mm steel plate with a single cutting edge and a 45 ° bevel angle:

Due to the extra 1-2mm edge of the board on site, our company's proposed solution is a dual machine collaborative operation, with the second milling machine following behind to clean the 1-2mm edge at an angle of 0 °. This way, the groove effect can be aesthetically pleasing and completed efficiently.

After using our edge milling machine for a period of time, the customer feedback shows that the processing technology of the steel plate has been greatly improved, and the processing difficulty has been reduced while the processing efficiency has doubled. We need to repurchase it in the future and recommend that our subsidiary and parent companies use our GMMA-80A plate beveling machine in their respective workshops.

Media Contact

Company Name: SHANGHAI TAOLE MACHINE CO.,LTD

Email: Send Email

Country: China

Website: https://www.bevellingmachines.com/